How to Choose the Best Harmonic Drive Company for Long-Term Cooperation

Harmonic drives, known for their smooth and precise power transmission, enable many tasks that are difficult or impossible for humans to perform. With the rapid development of AI and sensor technologies, humanoid robots are increasingly replicating human movement. As a result, harmonic drives are entering a trillion-dollar market era. Choosing a harmonic drive company for long-term cooperation has become a key topic among mechanical and robotics professionals.

1.The Manufacturer’s Core Strength

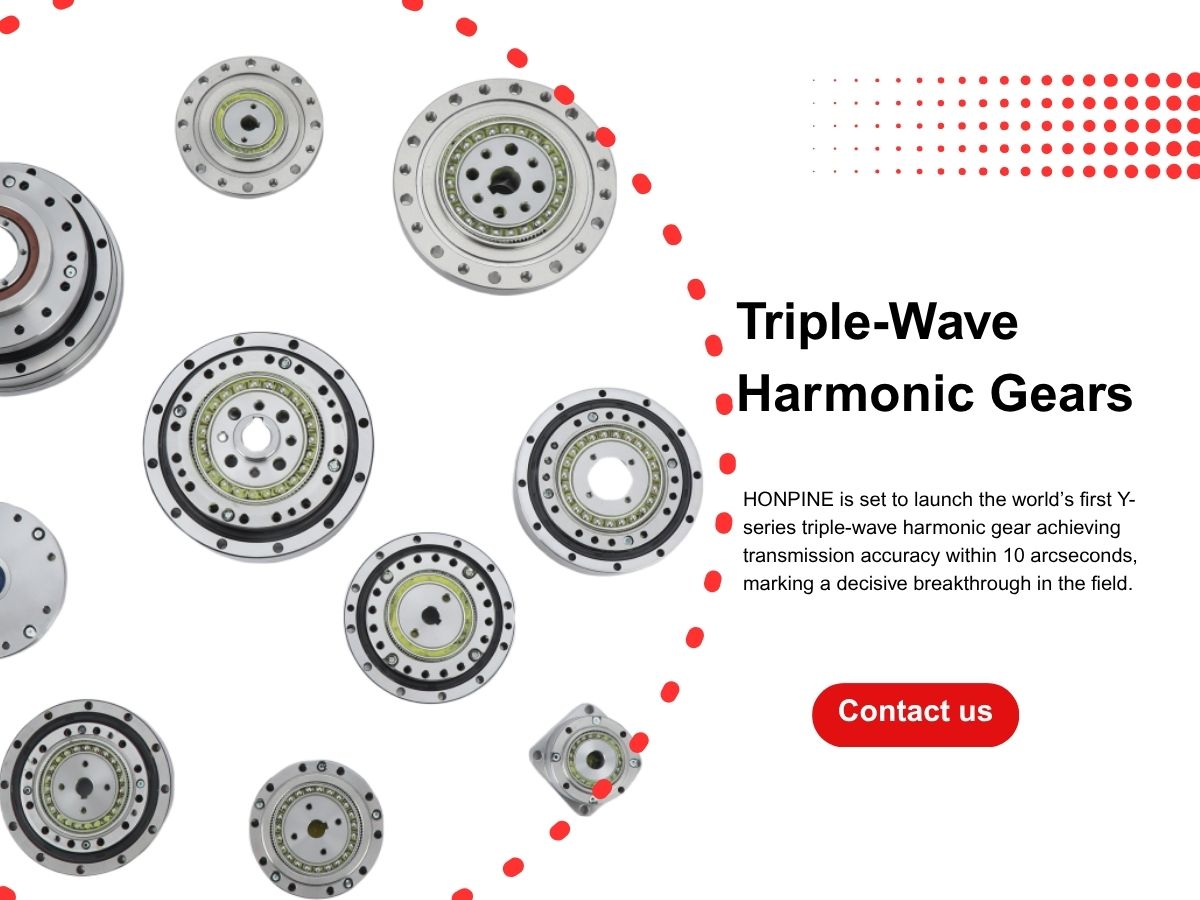

Harmonic drives are renowned for their high torque, near-zero backlash, and exceptional precision. Producing them, however, requires extremely advanced equipment and process control.

One of HONPINE’s greatest sources of confidence lies in our investment in such high-value manufacturing technology. We have introduced high-precision production machinery from Japan and Germany, and have established dedicated facilities for each stage of the production process.

Throughout manufacturing, we maintain strict control not only over precision and humidity but also over cleanroom conditions.

Between 2024 and 2026, HONPINE’s production facilities are moving toward greater automation and intelligence. More than one hundred collaborative robots have already been deployed on our production lines. HONPINE is breaking away from traditional manufacturing methods, exploring the deep boundaries of smart manufacturing together with our customers as we transition from Industry 4.0 to Industry 5.0.

Through real-time data interaction and AI-driven optimization, every production step is dynamically monitored and adaptively adjusted. This transformation not only improves production efficiency but also ensures product consistency and reliability.

As a result, HONPINE can quickly respond to market demand, provide customized solutions, and reduce operational costs.

2. Precision and Quality Matched to Application Needs

As niche applications continue to emerge, low-cost 3D-printed harmonic drives are becoming popular for DIY and educational use, where precision and lifespan requirements are low.

HONPINE, however, is committed to producing high-precision, long-life harmonic drives.

Our primary customers include industrial robots, CNC machines, semiconductor equipment, aerospace systems, medical devices, and the fast-growing humanoid robotics sector—all of which demand high reliability, long service life, and extreme accuracy.

3. Professional Technical Support — Before and After Sales

Selecting the right harmonic drive is critical. Even a small mismatch can lead to noise, poor precision, short service life, or assembly issues.

At HONPINE, our professional engineers provide one-on-one technical guidance during the selection process. We analyze specific drive parameters, mechanical compatibility, and environmental factors to recommend the most suitable model for each application.

This helps customers reduce testing costs and avoid blind selection. Our technical support continues after delivery, ensuring long-term cooperation and performance stability.

4. Customized Production Capability

Standard harmonic drives are typically designed around common servo interfaces, but real-world applications often require customized structures to fit limited installation spaces.

For example, humanoid robot and robotic arm joints often need special flange dimensions or compact layouts.

HONPINE supports both custom harmonic drives and integrated harmonic joint modules, providing flexible solutions for next-generation robotic systems.

5. Delivery Capacity

With the rapid growth of humanoid robots and industrial automation, global demand for harmonic drives is surging in 2025.

Leading brands such as Harmonic Drive Systems (Japan) and Leaderdrive (China) are already operating at full capacity.

As a rising force in the industry, HONPINE offers products whose parameters and measured performance are comparable to those of Harmonic Drive Systems and Leaderdrive, and our quality has been validated by the market.

6. Reasonable Pricing

For HONPINE, “reasonable price” does not mean “the lowest price.” It means pricing that aligns with performance and market standards.

Given the high precision required in harmonic drive manufacturing, excessively low prices often indicate compromised quality.

We encourage customers to start with sample testing, allowing them to directly verify HONPINE’s product quality and performance before large-scale adoption.

7. Quality Assurance System

HONPINE maintains stringent quality control over every harmonic drive we produce.

Before entering full production, each model undergoes reliability and lifespan testing.

We also send sample units to long-term customers for evaluation under real operating conditions before launching new products commercially.

Only after successful validation across multiple applications do we begin wider distribution—ensuring every HONPINE product meets the highest standards.

If you are also looking for a reliable harmonic drive supplier for long-term cooperation,

please contact HONPINE — your trusted partner in precision motion solutions.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand