Miniature Harmonic Drive Gearboxes Perfectly Match Bionic Animals

When selecting a harmonic drive gearbox for bionic organisms, several key factors must be considered — performance, structure, weight, and control.

Load-bearing joints (such as the hip, knee, and shoulder) require harmonic drives with higher torque, while flexible joints (such as the wrist, ankle, or fingers) demand compact, fast-response, low-inertia gearboxes.This article focuses on how miniature harmonic drive gearboxes are applied in bionic robots.

What Are Bionic Animals?

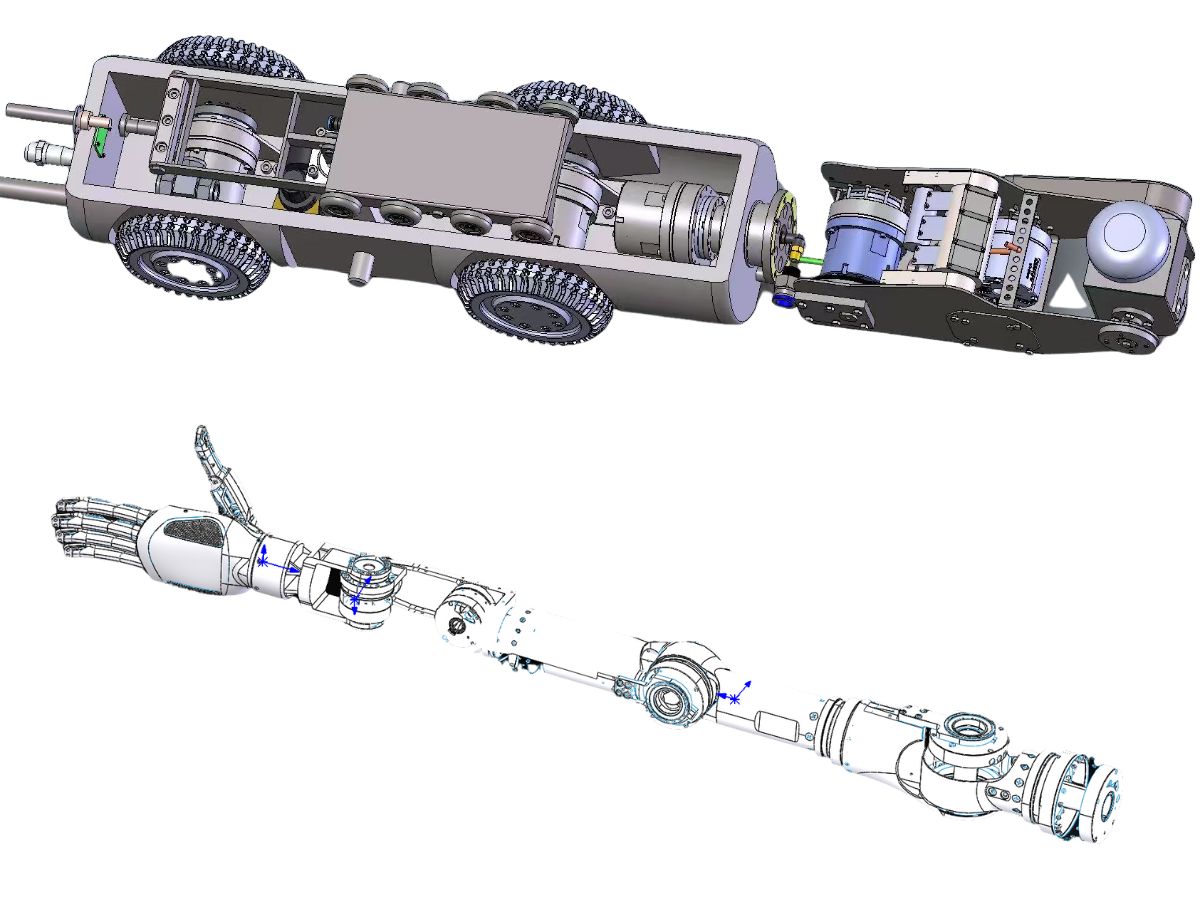

Bionic animals are robots designed to imitate various animal forms to perform specific tasks — often excelling in certain aspects beyond humanoid robots.

Quadruped Robots: Highly stable; used in inspection, exploration, and security applications.

Bionic Robotic Birds: Accurately mimic avian flight for research in aerodynamics and flight mechanics.

Robotic Snakes: Long, flexible bodies ideal for pipe inspection or search-and-rescue operations in confined spaces.

Robotic Fish: Simulate aquatic motion with low noise and high efficiency; used in marine exploration and environmental monitoring.

How Miniature Harmonic Drive Gearboxes Empower Bionic Animals

Miniature harmonic drive gearboxes provide the perfect combination of compact size, high torque, zero backlash, and high rigidity, making them a key enabling technology for achieving high performance, dexterity, and dynamic motion in bionic robots.

They directly address the central challenge in bionic actuation — how to fit powerful motion control into extremely limited space.

Why Miniature Harmonic Drive Gearboxes Fit Bionic Animals So Well

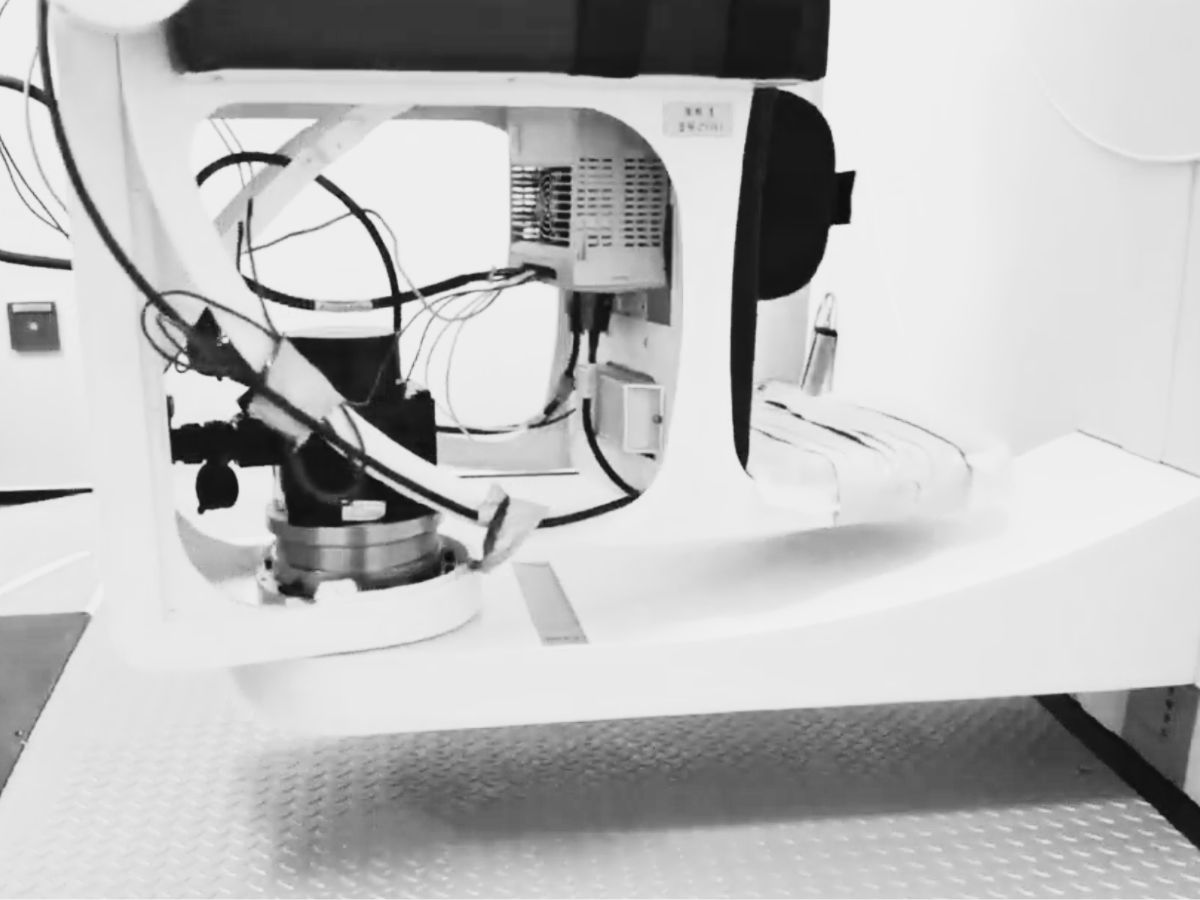

Miniature harmonic drive gearboxes come in small dimensions (outer diameters typically ranging from a few dozen millimeters down to less than twenty), making them ideal for the demanding requirements of bionic joints.

Miniaturization and lightweight design are crucial for realizing compact bionic joints.

These drives allow designers to embed powerful actuators into confined spaces that mimic animal skeletal structures, reducing end-effector weight and motion inertia.

Unlike conventional gear mechanisms with discrete tooth engagement, harmonic drives feature smooth, continuous meshing, which results in lower vibration and quieter operation.

Key Advantages:

High reduction ratio in a compact form

Zero backlash and high precision

High torque density and lightweight design

Smooth transmission and low noise

What Are the Limitations of Miniature Harmonic Drives?

High Cost: Precision manufacturing makes them more expensive than standard miniature planetary gearboxes.

Torque Ripple: Minor torque fluctuations may require compensation in applications demanding ultra-smooth motion.

Fatigue and Overload: The flexspline’s cyclic stress limits service life, and overload or impact may cause gear deformation or damage.

Despite challenges in cost and longevity, miniature harmonic drive gearboxes remain irreplaceable in bionic robotics where ultimate performance, compactness, and precision are required.Contact HONPINE to learn more about miniature harmonic drive solutions for bionic and robotic applications.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand