Industrial Robot Joint Servo Motor RV Cycloidal Reducer Gear Box

Standard RV Reducer

Standard RV (Rotary Vector) Reducer is a reduction device specially designed for precision machinery. It adopts a two-stage enclosed differential gear mechanism composed of a cycloidal pinwheel and a planetary gear set. The reducer itself is an open-type structure; therefore, during application, flange sealing and filling with dedicated RV grease are required.

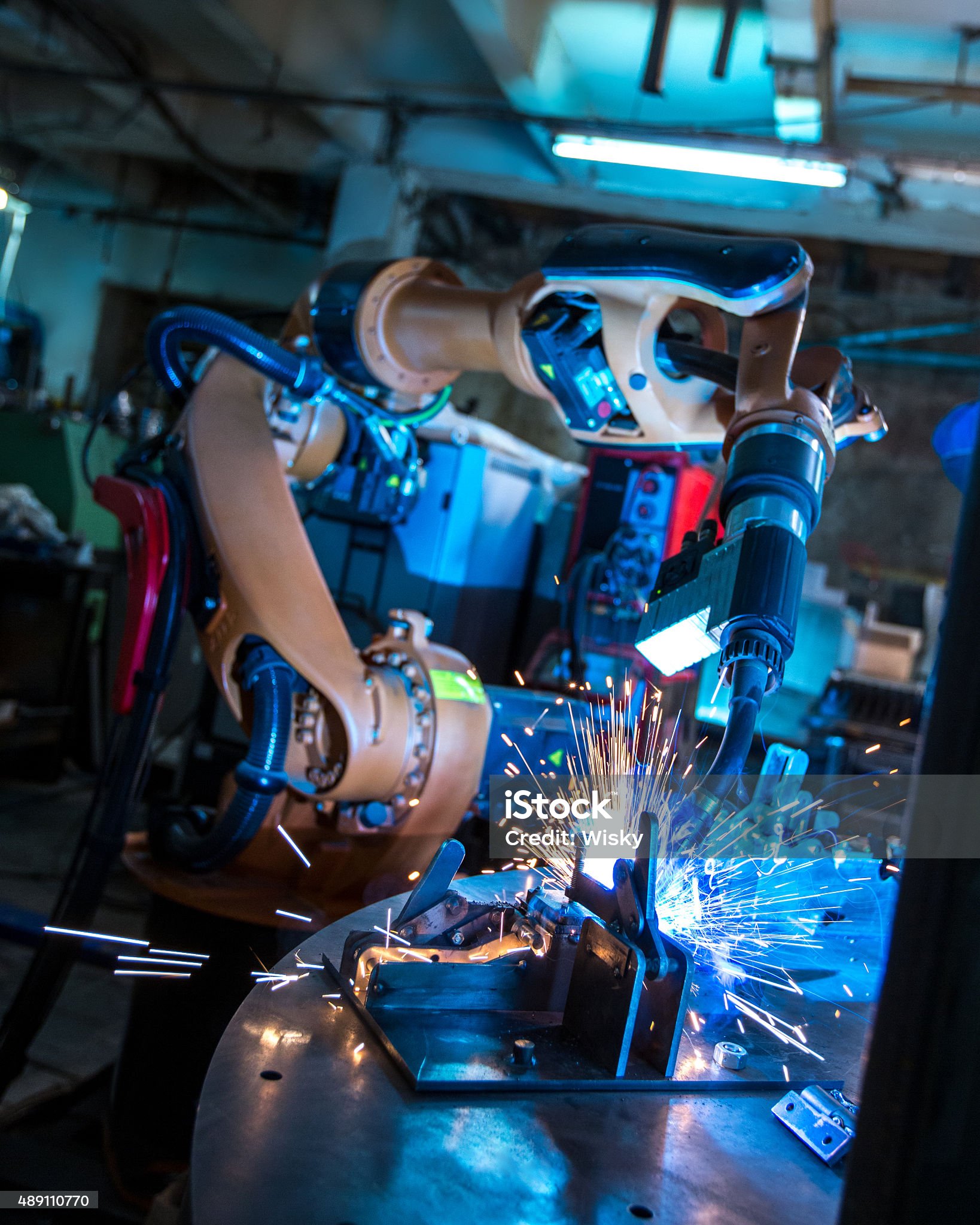

In the field of industrial robots, for robotic arms with an end payload of 20 kg or less, RV reducers are mainly applied to the base and high-load joints of the robot (typically joints 1 to 4). For robotic arms with an end payload exceeding 20 kg, all six joints (degrees of freedom) are equipped with RV reducers. The RV reducer is a core transmission component that ensures the positioning accuracy of robotic arms.

According to structural characteristics, standard RV reducers can be classified into:Standard E Series: solid-shaft structure,Standard C Series: hollow-shaft structure

Brief Usage Instructions

Both the Standard E Series and Standard C Series are open structures without flange sealing. After purchase, customers are required to perform flange sealing and inject dedicated RV lubricating grease. In addition, the solid input shaft supplied from the factory must be re-machined (shaft boring and keyway machining) according to the customer’s motor input shaft specifications.

Our company can provide custom secondary machining services for the input shaft based on the drawings supplied by the customer.

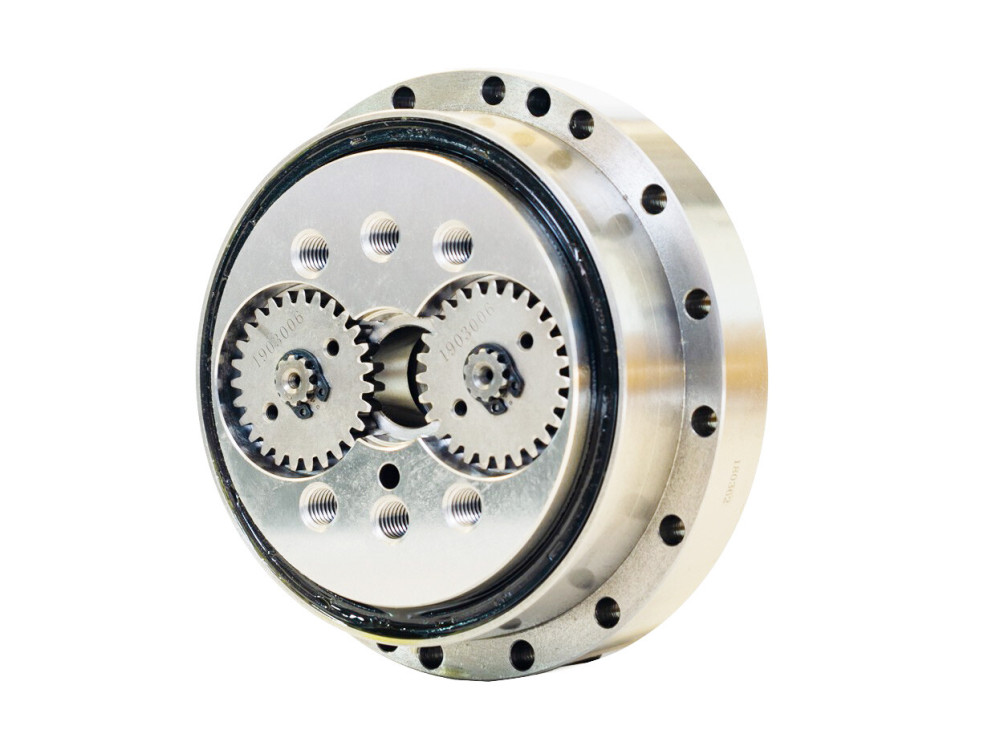

![Solid Output Shaft Planetary Gear Transmission RV Reducer for Heavy Duty Robotic Arms Solid Output Shaft Planetary Gear Transmission RV Reducer for Heavy Duty Robotic Arms]() Solid Output Shaft Planetary Gear Transmission RV Reducer for Heavy Duty Robotic ArmsThe Standard RV Reducer E Series is a precision reduction device featuring a two-stage closed differential gear system composed of a cycloid pinwheel and planetary gears, with a solid output shaft. It is widely used in industrial robotics applications.

Solid Output Shaft Planetary Gear Transmission RV Reducer for Heavy Duty Robotic ArmsThe Standard RV Reducer E Series is a precision reduction device featuring a two-stage closed differential gear system composed of a cycloid pinwheel and planetary gears, with a solid output shaft. It is widely used in industrial robotics applications.

For robotic arms with end loads ≤20 kg, RV reducers are primarily employed in base-to-high-load joints (typically Joints 1-4).

For robotic arms with end loads >20 kg, all six joints typically utilize RV reducers.

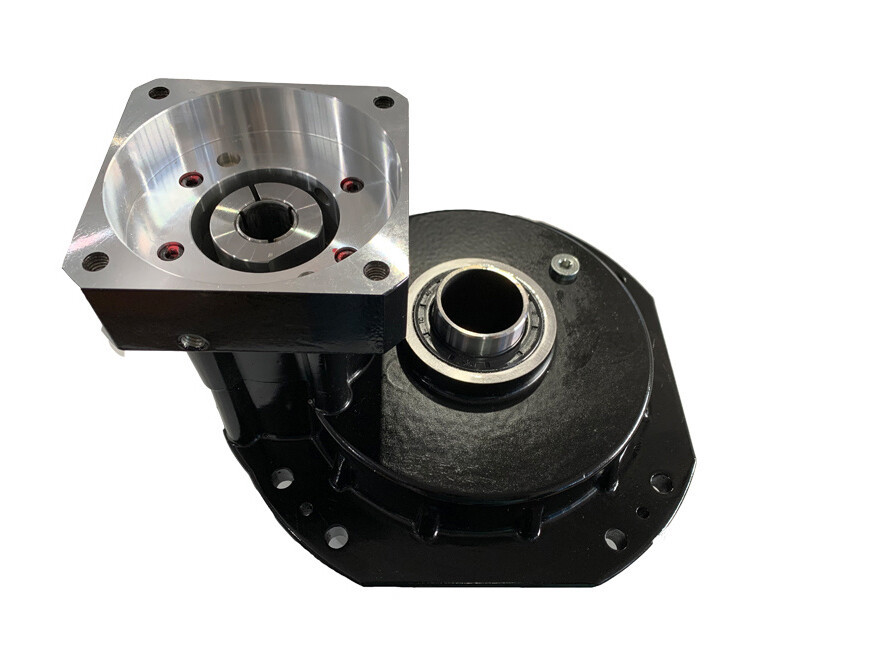

RV reducers serve as the core transmission component ensuring robotic arm positioning accuracy.Details![Precision Mechanical Hollow Output Shaft RV Reducer for Industrial Robotics Precision Mechanical Hollow Output Shaft RV Reducer for Industrial Robotics]() Precision Mechanical Hollow Output Shaft RV Reducer for Industrial RoboticsThe Standard RV Reducer C Series is a precision mechanical reduction device designed with a two-stage closed differential gear system, combining a cycloid pinwheel and planetary gear structure. It features a hollow output shaft and is widely used in industrial robotics.For robotic arms with end loads ≤20 kg, RV reducers are primarily used in base-to-high-load joints (typically Joints 1-4).For robotic arms with end loads >20 kg, all six joints typically use RV reducers.RV reducers are critical transmission components ensuring robotic arm positioning accuracy.Details

Precision Mechanical Hollow Output Shaft RV Reducer for Industrial RoboticsThe Standard RV Reducer C Series is a precision mechanical reduction device designed with a two-stage closed differential gear system, combining a cycloid pinwheel and planetary gear structure. It features a hollow output shaft and is widely used in industrial robotics.For robotic arms with end loads ≤20 kg, RV reducers are primarily used in base-to-high-load joints (typically Joints 1-4).For robotic arms with end loads >20 kg, all six joints typically use RV reducers.RV reducers are critical transmission components ensuring robotic arm positioning accuracy.Details

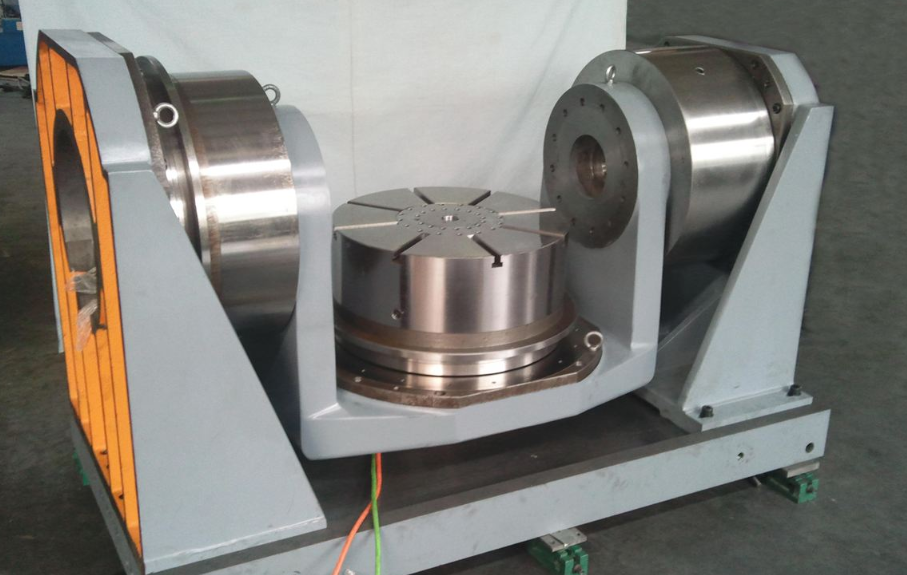

Flange RV Reducer

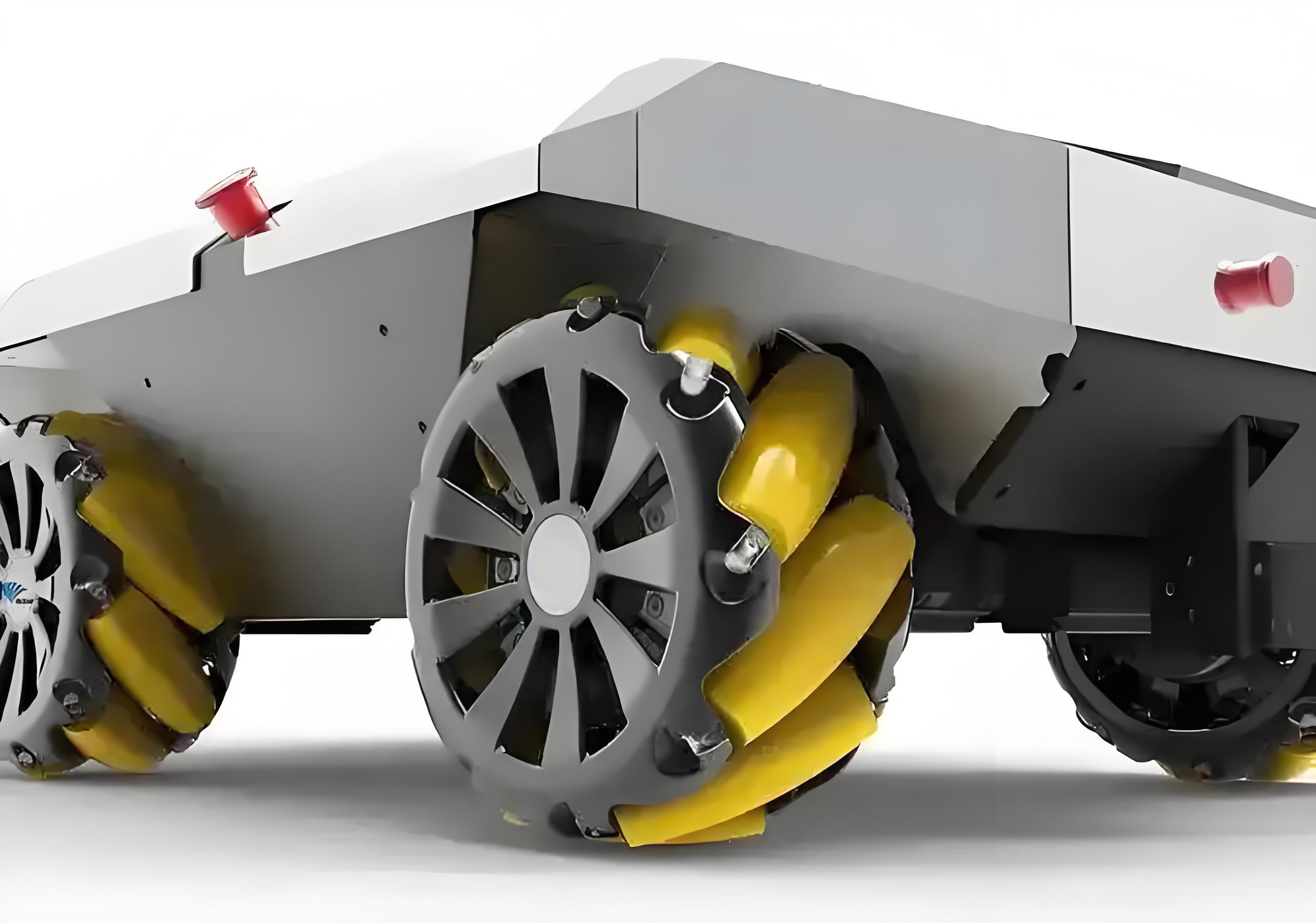

Flange-Integrated RV (Rotary Vector) Reducer is a reduction device specifically designed for precision machinery. It adopts a two-stage enclosed differential gear mechanism composed of a cycloidal pinwheel and a planetary gear set. The reducer is factory-assembled with an integrated flange-sealed structure and pre-filled with dedicated RV lubricating grease, allowing customers to use it directly with a servo motor out of the box.

In the field of industrial robots, for robotic arms with an end payload of 20 kg or less, RV reducers are mainly applied to the base and high-load joints of the robot (typically joints 1 to 4). For robotic arms with an end payload exceeding 20 kg, all six joints (degrees of freedom) are equipped with RV reducers. The RV reducer is a core transmission component that ensures the positioning accuracy of robotic arms.

The flange-integrated RV reducer is a customized model developed by adding flange sealing to the standard RV reducer. According to the same classification characteristics as standard RV reducers, flange-integrated RV reducers can be divided into:Flange-Integrated E Series: solid-shaft structure,Flange-Integrated C Series: hollow-shaft structure

![High Precision Two Stage Serve Motor Flange RV Reducer High Precision Two Stage Serve Motor Flange RV Reducer]() High Precision Two Stage Serve Motor Flange RV ReducerThe Flange-Integrated RV Reducer E Series represents a precision-engineered speed reduction solution designed for high-performance mechanical applications. This advanced transmission system features a two-stage enclosed differential gear mechanism combining cycloidal pin gear and planetary gear configurations, with a solid output shaft design. The unit comes factory-assembled with flange sealing and pre-lubricated with specialized RV grease, enabling immediate integration with servo motors upon installation.

High Precision Two Stage Serve Motor Flange RV ReducerThe Flange-Integrated RV Reducer E Series represents a precision-engineered speed reduction solution designed for high-performance mechanical applications. This advanced transmission system features a two-stage enclosed differential gear mechanism combining cycloidal pin gear and planetary gear configurations, with a solid output shaft design. The unit comes factory-assembled with flange sealing and pre-lubricated with specialized RV grease, enabling immediate integration with servo motors upon installation.

Industrial Robotics Applications:

For robotic arms with end-effector payloads ≤20kg: Primarily deployed in base-to-high-load joints (typically J1-J4)

For robotic arms with end-effector payloads >20kg: All six joints utilize RV reducers

As the critical transmission component, RV reducers ensure exceptional positioning accuracy in robotic systems.Details![Hollow Output Shaft Flange Integrated Cycloid RV Robot Gearbox Hollow Output Shaft Flange Integrated Cycloid RV Robot Gearbox]() Hollow Output Shaft Flange Integrated Cycloid RV Robot GearboxThe Flange-Integrated RV Reducer C Series is a precision reduction device specifically designed for mechanical applications. It features a two-stage closed differential gear system consisting of cycloid pinwheels and planetary gears, with a hollow output shaft. The unit comes factory-sealed with flanges and pre-filled with specialized RV lubricating grease, allowing direct installation with servo motors upon unboxing.

Hollow Output Shaft Flange Integrated Cycloid RV Robot GearboxThe Flange-Integrated RV Reducer C Series is a precision reduction device specifically designed for mechanical applications. It features a two-stage closed differential gear system consisting of cycloid pinwheels and planetary gears, with a hollow output shaft. The unit comes factory-sealed with flanges and pre-filled with specialized RV lubricating grease, allowing direct installation with servo motors upon unboxing.

In industrial robotics applications:

For robotic arms with end-effector loads ≤20kg, RV reducers are primarily used in base-to-high-load joints (typically Joints 1-4)

For robotic arms with end-effector loads >20kg, all six joints typically employ RV reducers

RV reducers serve as the core transmission component ensuring robotic arm positioning accuracy.Details

Why Choose HONPINE RV Reducer Gearbox

1,With proprietary tooth profile design, modification technology, and strong technical support, we can mass-produce core components with rational force distribution, self-adaptation to manufacturing errors, strong damage resistance, smooth transmission, and low noise levels.

2,HONPINE possesses world-class high-precision CNC production equipment, customized to ensure stability and efficiency in high-precision batch machining.

3,Our self-developed machining processes, along with high-precision and high-efficiency clamping fixtures, guarantee product accuracy, stability, and production efficiency.

4,We independently developed specialized batch inspection tools, testing instruments, and test benches to achieve rapid batch testing with automatic data entry into the database.

5,Our self-developed assembly tools and tolerance allocation methods enhance both efficiency and precision in batch assembly operations.

6,In collaboration with partners, we developed dedicated heat treatment equipment to ensure superior and consistent material properties in mass-produced components. Precise heat treatment control guarantees stable reducer quality.

7,Equipped with a professional testing platform (benchmarked against national evaluation centers), we can evaluate the overall performance of RV reducer gearboxes and provide official test reports.

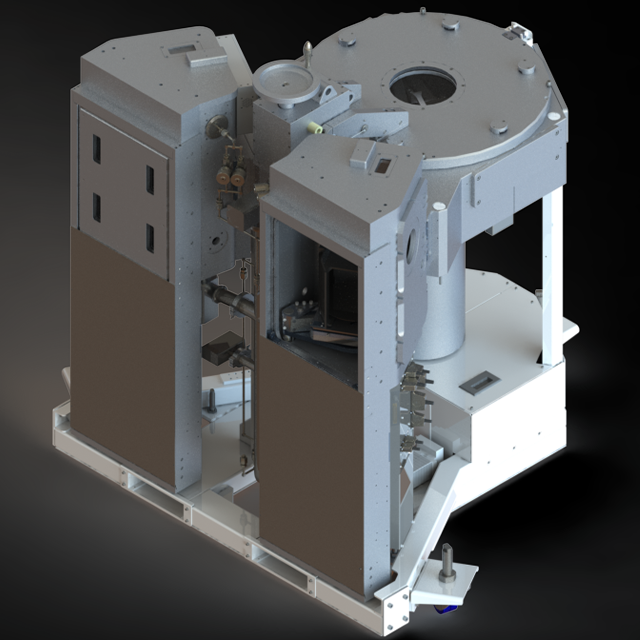

Application of Precision Planetary Reducer Gearbox

RV (Rotary Vector) reducers deliver ultra-high torque capacity, exceptional rigidity, and outstanding shock resistance in heavy-duty applications. Their unique two-stage reduction structure ensures high precision and minimal backlash under demanding conditions.

Designed for industrial robots, machine tools, automation systems, and other high-precision applications requiring robust performance under extreme loads.

We also offer flange-integrated models for direct motor mounting, simplifying installation and improving system integration.

Choose our RV series for reliable performance, long service life, and customized solutions tailored to your industrial needs.

RV Reducer Gearboxes - FAQ

An RV reducer (Rotary Vector Reducer) is a high-precision speed reducer designed for motion control applications, featuring a planocentric reduction mechanism.

Its core lies in a two-stage reduction design:

1. First Stage Reduction – Spur Gear Mechanism:

The input shaft transmits rotation through the input gear to the spur gear, achieving primary speed reduction.

2. Second Stage Reduction – Differential Gear Mechanism:

The spur gear is connected to a crankshaft, which drives the RV gear in an eccentric motion.

The RV gear has one tooth fewer than the pin gear, thus achieving a high reduction ratio.

Rated Torque (To):

The allowable torque when operating at the rated output speed — not the absolute load limit.

Allowable Starting/Stopping Torque (Ts1):

The maximum torque allowed during acceleration and deceleration, typically 2.5 times the rated torque.

Maximum Instantaneous Torque (Ts2):

The allowable torque during emergency stops or impacts, typically 5 times the rated torque.

Allowable Output Speed (Ns0):

The maximum output speed under no-load conditions, affected by temperature and load.

Backlash and Lost Motion:

Backlash refers to the torsional angle when torque is zero;

lost motion refers to the hysteresis curve width within ±3% of the rated torque.

RV reducers usually maintain backlash within 1 arcminute.

Torsional Stiffness:

The torque required per unit of torsional angle — reflects the reducer’s resistance to deformation.

Service Life:

The rated service life is typically 6,000 hours under rated torque and speed.

Installation Accuracy:

Ensure flatness and perpendicularity of the mounting surface to avoid eccentric loads.

It’s recommended to use a dial gauge, keeping vibration amplitude within 0.02 mm.

Lubricant Selection:

Common lubricants include VIGOGREASE REO.

Standard replacement cycle: 20,000 hours; shorten the interval under high-temperature conditions.

Temperature Management:

Surface temperature must not exceed 60°C.

If exceeded, use cooling measures or derate operation.

Small-Angle Operation:

When the rotation angle is less than 10°, lubrication may be insufficient — consult the manufacturer.

Bolt Tightening:

Use disc spring washers and hex socket bolts, tightened to standard torque to prevent loosening.

The HONPINE Flange RV Reducer Gearbox adopts a flange-sealed design, which encloses the lubricant and motor inside.

This simplifies installation, extends service life, and reduces maintenance needs.

When selecting an RV reducer, consider installation orientation, structural form, operating conditions, and environment.

Calculate load inertia and steady torque, set the operating mode, and determine acceleration/deceleration torque, average speed, and average load torque.

Finally, calculate the required rated torque based on service life requirements.

For detailed selection guidance, please contact HONPINE for professional assistance.

Contact Information

Phone/WhatsApp: +86 18994329920

Email: sales@honpine.com

Industrial robots are the primary application field for RV reducers.

The core advantages of an RV reducer include high rigidity, high precision, large transmission ratio, and long service life — making it irreplaceable, especially in heavy-load robotic joints.

The fundamental function of an RV reducer is to convert the motor’s high-speed, low-torque output into low-speed, high-torque power, ensuring precise motion control.

Transmission accuracy can typically reach arc-second levels, and the service life commonly exceeds 10,000 hours.

The HONPINE RV Reducer Gearboxes achieves exceptional precision, rigidity, and durability through advanced tooth profile optimization and structural engineering.

Its core technologies include:

Optimized cycloidal gear tooth design

Integrated housing structure for higher rigidity and stability

Optimized bearing configuration to ensure smooth torque transmission

Key components such as cycloidal gears and pin rollers are made from high-strength alloy steel and special composite materials, providing superior strength, wear resistance, and toughness.

Enhanced material performance significantly extends product life — with a rated service life exceeding 15,000 hours, meeting the requirements of high-end robotic applications.

HONPINE’s optimized heat treatment process further improves component hardness and stability, reduces wear rates, and minimizes performance degradation under continuous operation.

- 00

0000-00

OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor![OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor]()

- 00

0000-00

The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines![The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines]()

- 00

0000-00

Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?![Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems? Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?]()

- 00

0000-00

What is the Difference Between RV Reducer and Harmonic Reducer?![What is the Difference Between RV Reducer and Harmonic Reducer? What is the Difference Between RV Reducer and Harmonic Reducer?]()

- 00

0000-00

Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?![Why Are Harmonic Rotary Actuators Perfect for Medical Equipment? Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?]()

- 00

0000-00

Harmonic Drive Gearbox – Complete Introduction and Analysis![Harmonic Drive Gearbox – Complete Introduction and Analysis Harmonic Drive Gearbox – Complete Introduction and Analysis]()